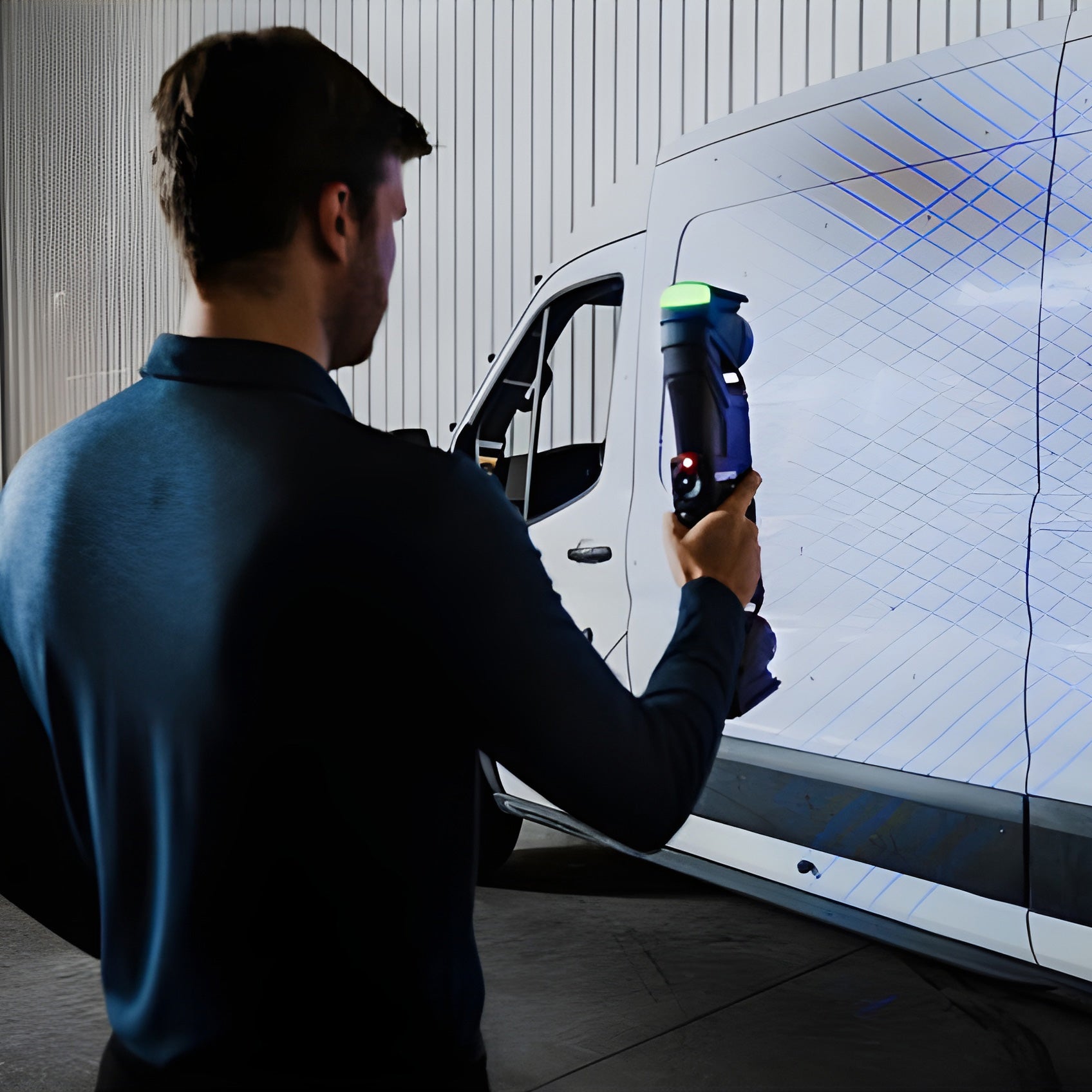

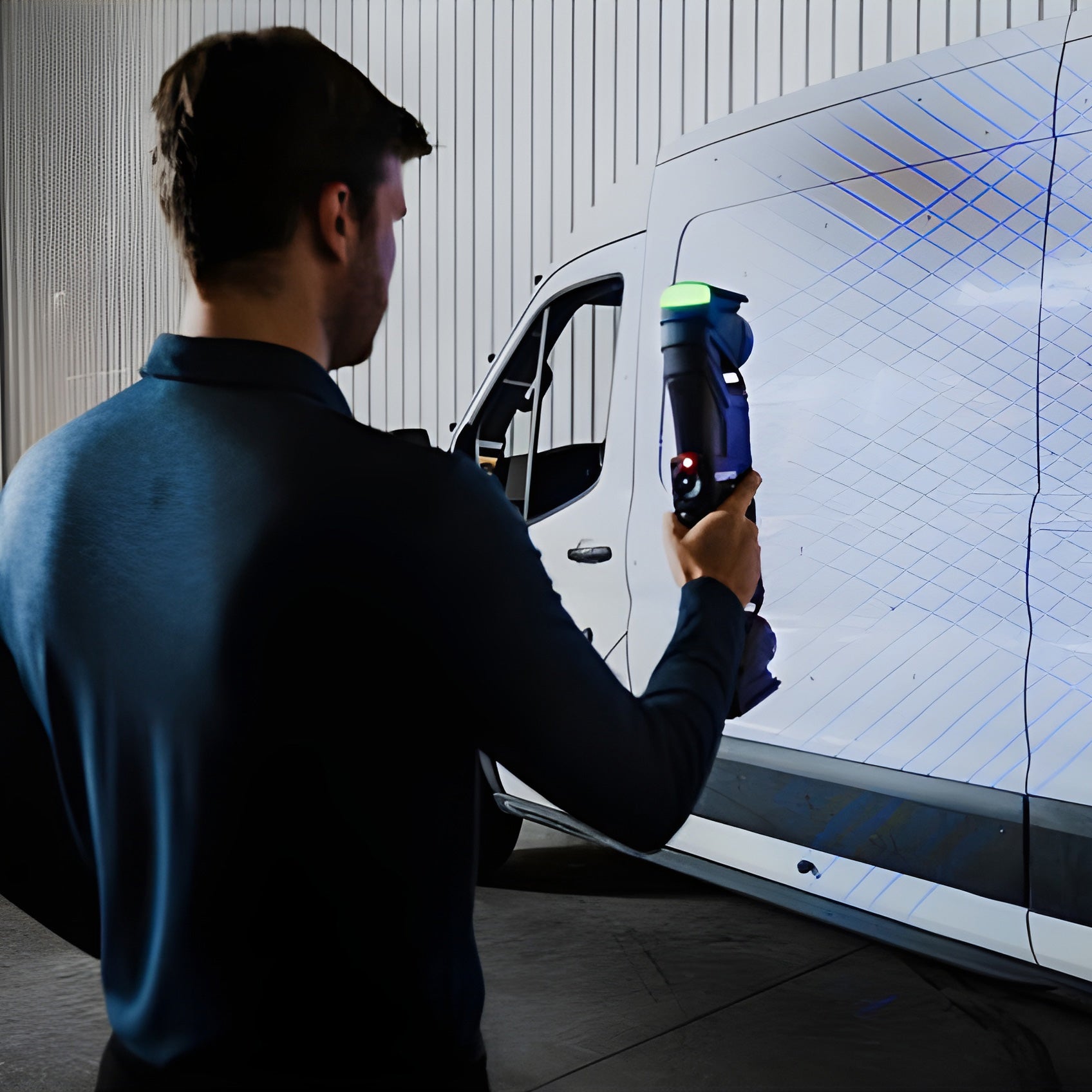

We start by 3D scanning each van to capture its exact geometry. This ensures our components follow the vehicle’s lines perfectly—down to the millimeter—for a clean, secure fit every time.

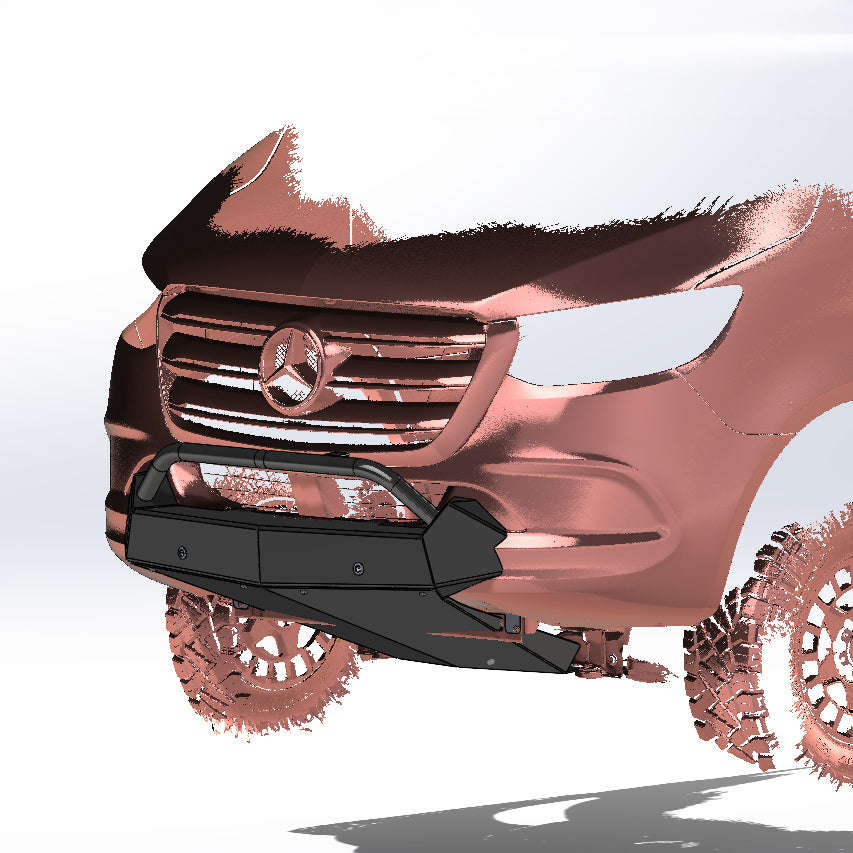

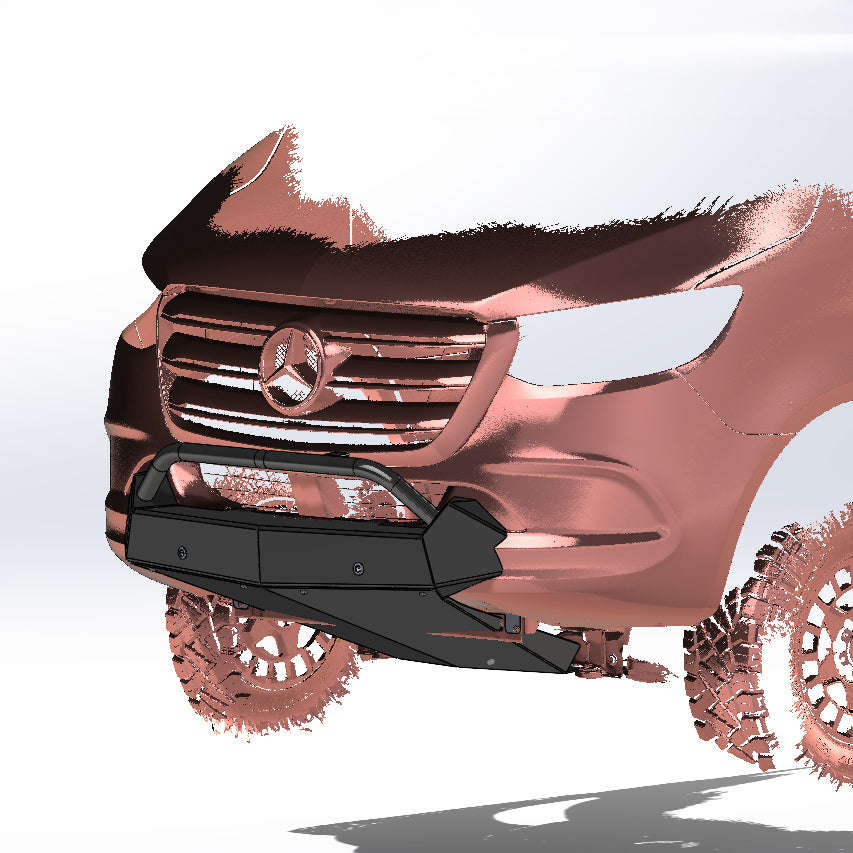

Once the vehicle is scanned, we design each part in 3D CAD software using real scan data. This allows us to model everything with exact tolerances and verify alignment before anything is made.

Raw aluminum sheets are laser-cut with micron-level accuracy. This step guarantees clean edges, tight part fitment, and maximum material efficiency—laying the foundation for long-lasting quality.

Each component is CNC bent using high-tonnage press brakes. This process gives the metal strength and shape while preserving dimensional accuracy throughout the build.

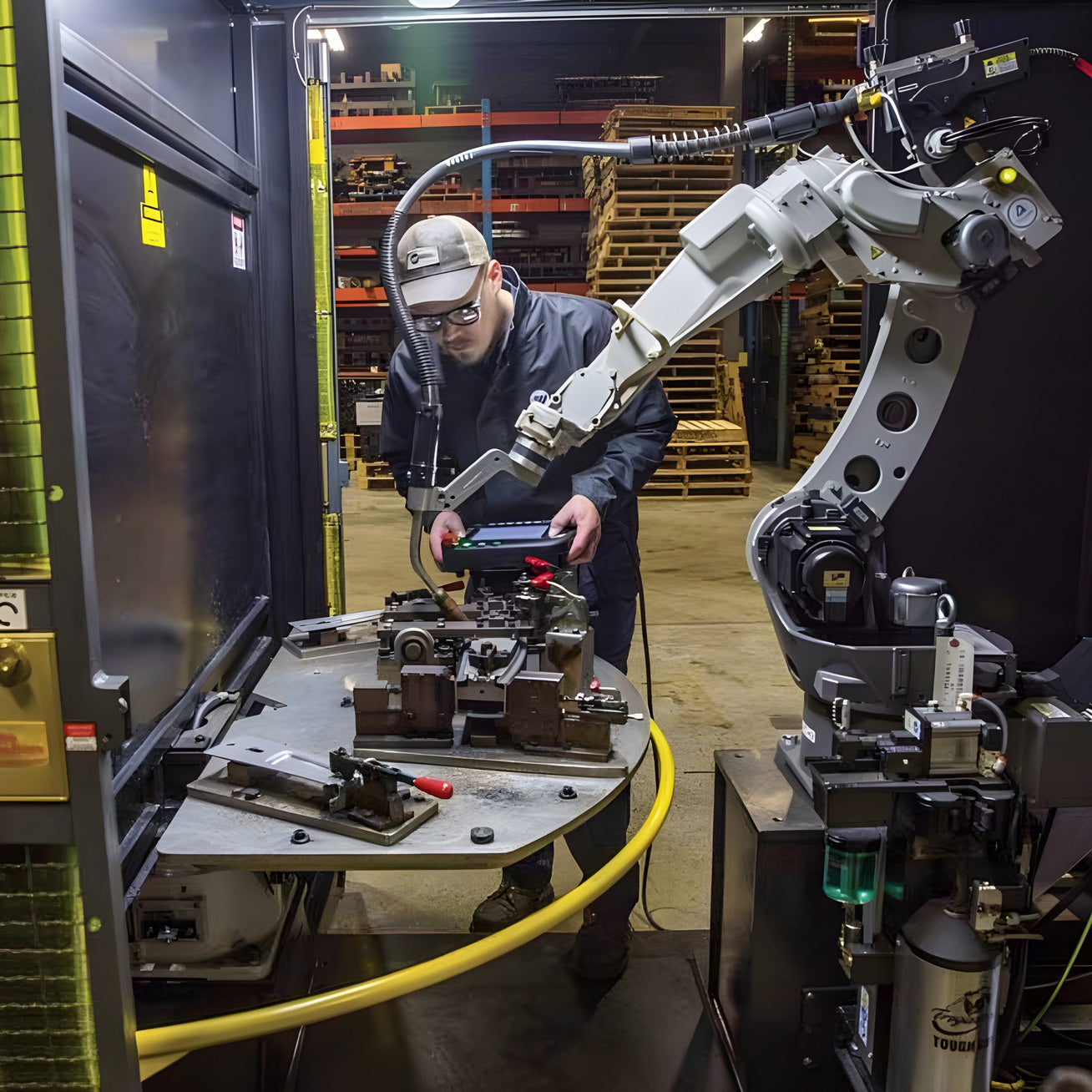

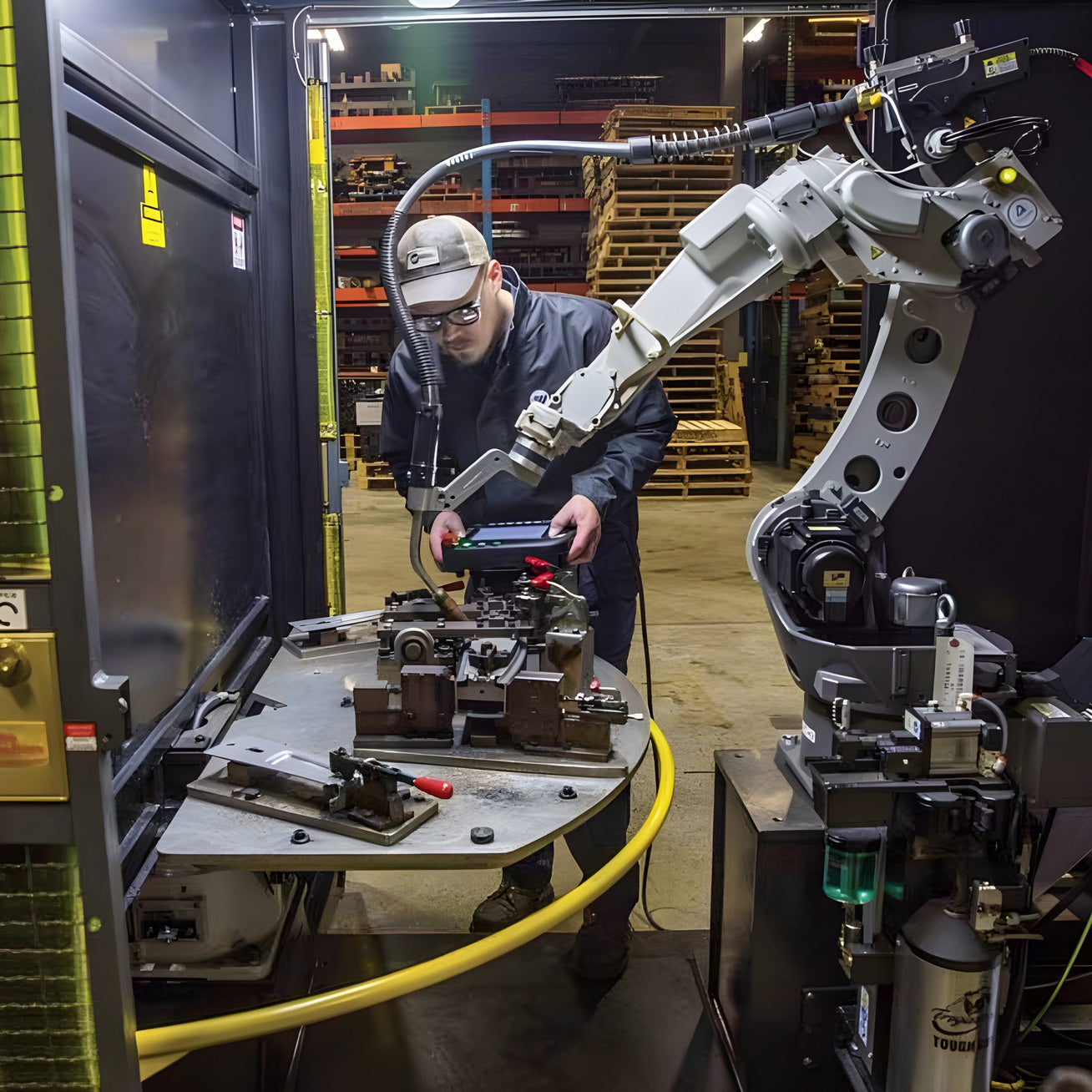

Our robotic welding systems ensure every weld is clean, repeatable, and strong. This eliminates variation and human error, delivering reliable performance in every piece we ship.

Finished parts are powder-coated for durability, then assembled, packed, and shipped. Each product arrives ready to install.

We start by 3D scanning each van to capture its exact geometry. This ensures our components follow the vehicle’s lines perfectly—down to the millimeter—for a clean, secure fit every time.

Once the vehicle is scanned, we design each part in 3D CAD software using real scan data. This allows us to model everything with exact tolerances and verify alignment before anything is made.

Raw aluminum sheets are laser-cut with micron-level accuracy. This step guarantees clean edges, tight part fitment, and maximum material efficiency—laying the foundation for long-lasting quality.

Each component is CNC bent using high-tonnage press brakes. This process gives the metal strength and shape while preserving dimensional accuracy throughout the build.

Our robotic welding systems ensure every weld is clean, repeatable, and strong. This eliminates variation and human error, delivering reliable performance in every piece we ship.

Finished parts are powder-coated for durability, then assembled, packed, and shipped. Each product arrives ready to install.